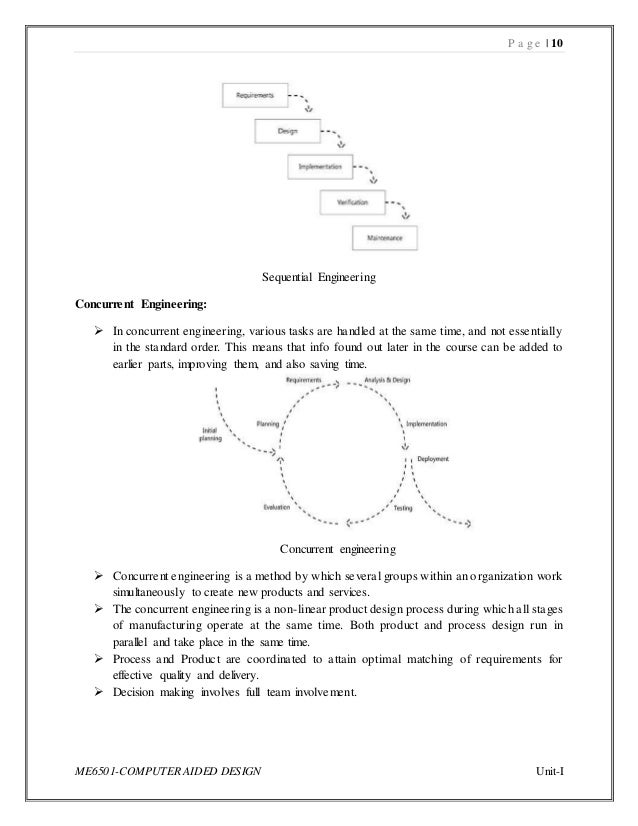

Sequential Engineering

Sequential Engineering Advantages

SEQUENTIAL AND CONCURRENT ENGINEERING With today's marketplace becoming more and more competitive, there is an ever-increasing pressure on companies to respond quickly to market needs, be cost effective, reduce lead-times to market and deliver superior quality products. Traditionally, design has been carried out as a sequential set of activities with distinct non-overlapping phases. In such an approach, the life-cycle of a product starts with the identification of the need for that product. These needs are converted into product requirements which are passed on to the design department. The designers design the product's form, fit, and function to meet all the requirements, and pass on the design to the manufacturing department.

After the product is manufactured it goes through the phases of assembly, testing, and installation. This type of approach to life-cycle development is also known as `over the wall' approach, because the different life-cycle phases are hidden or isolated from each other. Each phase receives the output of the preceding phase as if the output had been thrown over the wall.

In such an approach, the manufacturing department, for example, does not know what it will actually be manufacturing until the detailed design of the product is over. Figure.1.8.Over the Wall Engineering (Sequential Engineering) There are a lot of disadvantages of the sequential engineering process.